The automotive world never stops it’s a high-speed engine of innovation, jobs, and economic growth. But every minute of unplanned downtime? That’s a whopping

$22,000 flying out the window. No wonder 82% of automotive companies have faced these pesky disruptions in just the last three years, throwing efficiency, delivery schedules, and profits off track. So, how can manufacturers and fleet operators stay in the fast lane without hitting these costly roadblocks?

Enter predictive maintenance. By tapping into AI, IoT sensors, and real-time analytics, companies can spot trouble before it slows them down. McKinsey reports that predictive maintenance can cut costs by 10–40% and shave downtime by up to 30%.

The question isn’t whether it works it’s who can deliver it with precision and scale.

That’s where

Radome Technologies steps in. With smart AI diagnostics, seamless IoT integration, and cloud-based insights, Radome empowers automotive manufacturers and fleet operators to keep downtime in check, costs under control, and operations functioning optimally.

The automotive sector stands as one of the most dynamic pillars of manufacturing, driving innovation, creating jobs, and contributing significantly to national economic growth. With every minute of unplanned downtime costing $22,000 in losses every minute, the stakes are higher than ever. In fact, 82% of automotive companies have experienced unplanned downtime incidents in the past three years, which have directly impacted efficiency, delivery schedules, and profitability. So how can manufacturers and fleet operators stay ahead of these costly disruptions?

This is where predictive maintenance in automotive industry solutions come into play. By using AI, IoT sensors, and real-time analytics, companies can anticipate issues before they escalate. According to McKinsey, predictive maintenance reduces costs by 10–40% and cuts downtime by up to 30%. The real question becomes: who can deliver these results with precision and scalability?

That’s where Radome Technologies steps in. With AI diagnostics, IoT integration, and cloud-based analytics, Radome Technologies' automotive predictive maintenance solutions empower manufacturers and fleets to minimize downtime, reduce costs, and keep operations running at peak efficiency.

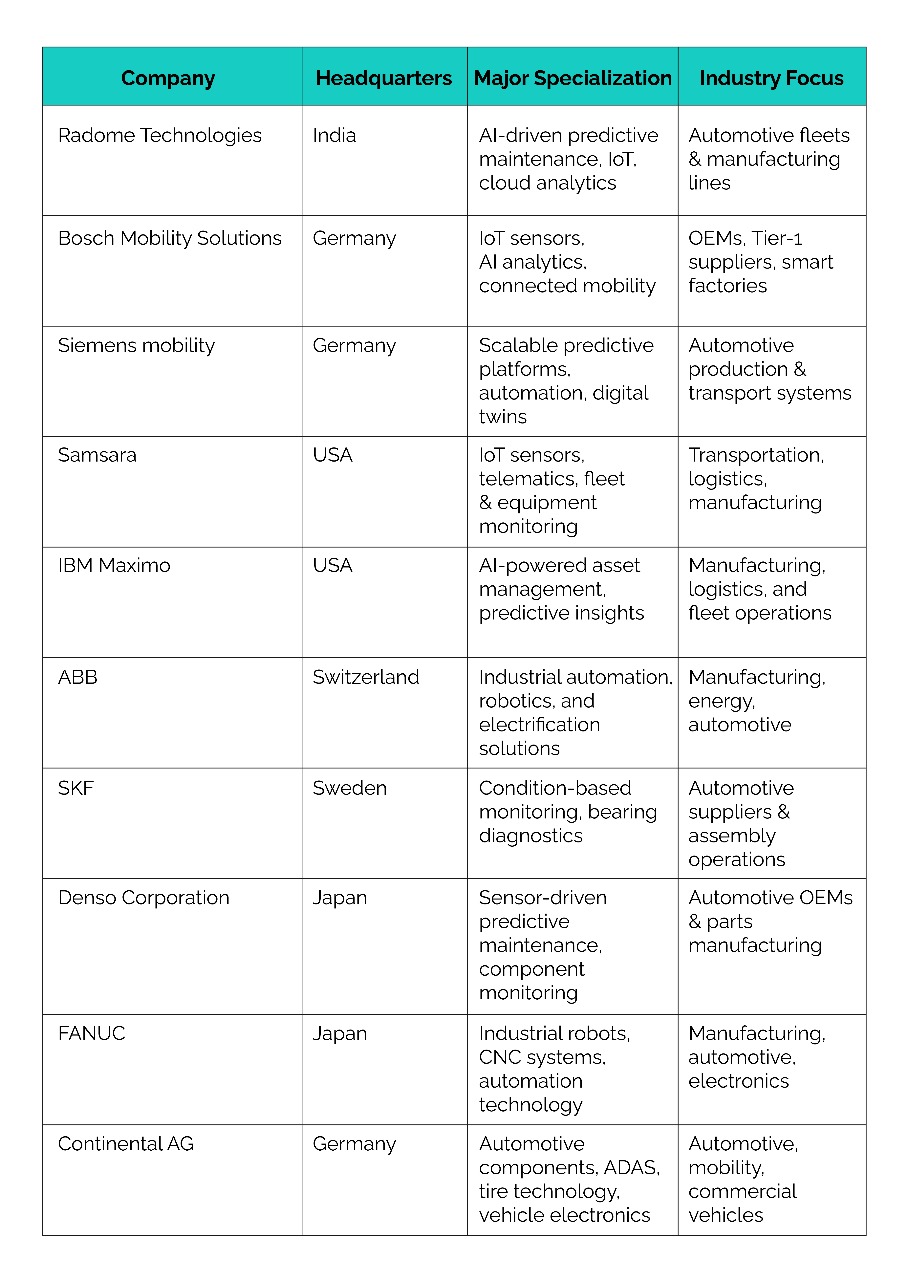

Top 10 Companies Offering Predictive Maintenance in the Automotive Industry

Below are the top 10 businesses that are innovating predictive maintenance automotive industry:

1.Radome Technologies

Radome Technologies is an emerging leader redefining how predictive maintenance is applied in the automotive industry. Unlike legacy providers, Radome Tech offers a purpose-built, intelligent platform that combines AI diagnostics, advanced machine learning, IoT-enabled sensors, and cloud analytics into a seamless solution.

With Radome technologies, automotive manufacturers and fleet operators can:

-

Reduce unplanned downtime by up to 30% through real-time anomaly detection.

.

-

Cut maintenance costs by 20–25% by replacing parts only when necessary.

.

-

Boost vehicle uptime and safety, ensuring compliance and performance.

.

What sets Radome Tech apart is its laser focus on the automotive sector. Rather than providing one-size-fits-all solutions, Radome tech tailors its systems to the unique challenges of vehicle fleets, assembly lines, and automotive suppliers. Its solutions not only monitor and predict failures but also provide data-driven insights that drive continuous improvement.

Additionally, Radome Tech emphasizes easy integration with existing systems, making adoption smooth for companies without disrupting ongoing operations. Backed by a commitment to innovation, Radome Technologies positions itself as a partner for future-ready automotive businesses seeking to achieve efficiency, safety, and competitiveness in a rapidly evolving landscape.

2.Bosch Mobility Solutions

Bosch has long been a leader in automotive technology, and its predictive maintenance offerings are no exception. By integrating AI-driven analytics with IoT sensors, Bosch enables manufacturers and fleet operators to monitor vehicle health in real-time. This approach not only reduces unplanned downtime, and also extends component lifecycles

3.Siemens Mobility

Siemens Mobility applies decades of industrial automation expertise to the automotive sector, offering predictive maintenance solutions that are both scalable and deeply integrated with manufacturing operations. Its platforms leverage IoT-enabled sensors, digital twins, and real-time analytics to predict component wear and production line inefficiencies.

4.Samsara

Samsara provides solutions that empower businesses to monitor their fleets, equipment, and industrial operations in real-time. Their platform provides predictive insights that reduce downtime, optimize maintenance schedules, and enhance operational efficiency across the transportation, logistics, and manufacturing sectors.

5.IBM Maximo

IBM Maximo has carved a strong niche in asset performance management. Its predictive maintenance solution leverages AI and cloud technology to analyze data from vehicles and machinery, enabling early fault detection. Automotive companies using Maximo have achieved reductions in downtime, along with measurable increases in asset longevity.

6.ABB

ABB focuses on industrial automation, robotics, and electrification solutions. Their predictive maintenance and smart factory platforms enhance operational efficiency, minimize unplanned downtime, and streamline production lines in manufacturing, energy, and automotive industries. ABB’s scalable solutions support both large enterprises and regional operations.

7.SKF

SKF is renowned for its expertise in bearings and condition monitoring systems, and it brings this heritage into predictive maintenance. Its automotive-focused solutions deliver real-time data on vibration, temperature, and wear patterns to detect early signs of failure. Companies adopting SKF’s platforms have cut maintenance costs while improving reliability across fleets and production equipment.

8. Denso Corporation

As one of the largest automotive component manufacturers, Denso integrates predictive maintenance into its offerings to enhance vehicle reliability. By analyzing sensor data from critical systems, Denso helps operators intervene before issues escalate. These solutions have reduced component failure rates while improving safety and efficiency.

9. FANUC

FANUC targets industrial robotics, CNC systems, and automation technology for advanced manufacturing. Their predictive maintenance solutions help companies optimize machine uptime, reduce component wear, and improve production precision across automotive, electronics, and general manufacturing sectors.

10.Continental AG

Continental AG combines automotive components, vehicle electronics to enhance safety, reliability, and performance. Their predictive maintenance and sensor-driven solutions help OEMs and fleet operators monitor critical systems, prevent failures, and improve operational efficiency in the automotive and commercial vehicle sectors.

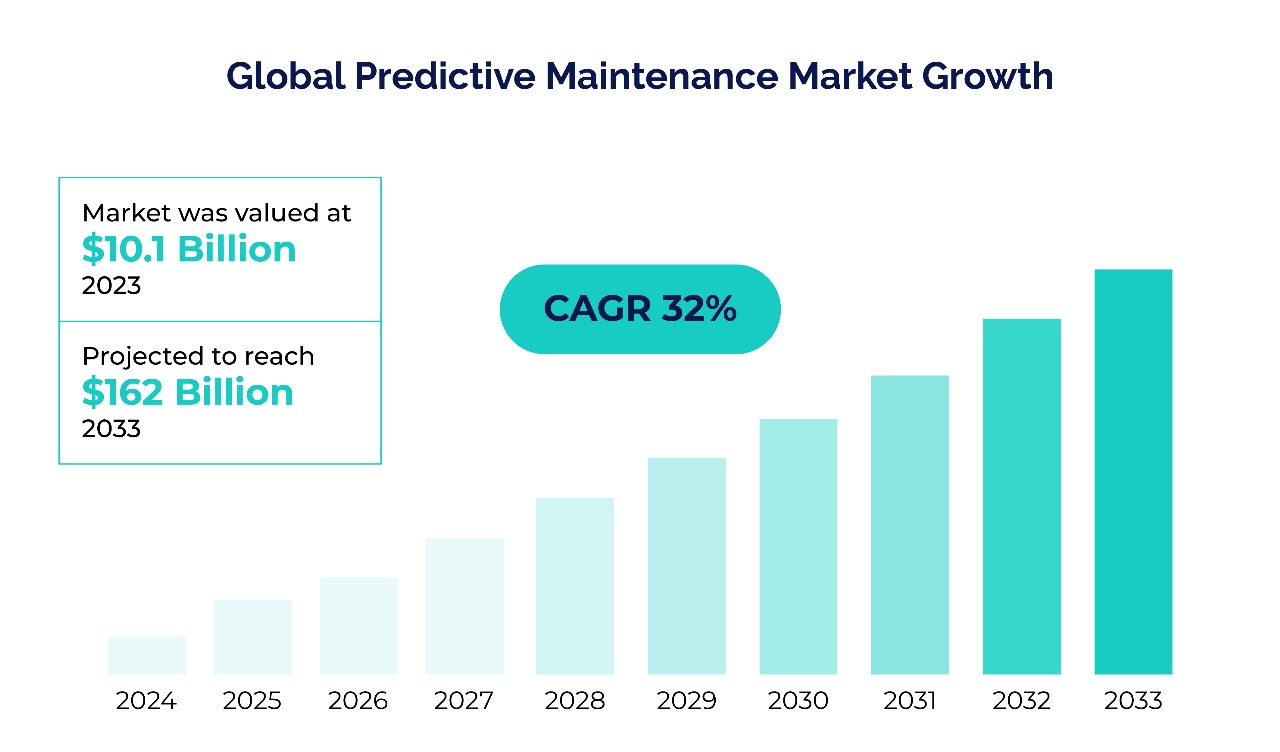

Let’s have a glance at the industry growth potential and its market size:

Market Insights: Growth and Opportunities

According to the study conducted by Allied Market Research, the global predictive maintenance market in automotive is projected to reach $162 billion by 2033, growing at a CAGR of 32%. Factors driving this growth include:

-

The rise of electric vehicles requires specialized monitoring.

.

-

Increasing adoption of connected car technologies.

.

-

Regulatory pressures to enhance vehicle safety and emissions compliance.

.

In Summary

Predictive maintenance in automotive industry is no longer optional it’s a business-critical strategy. Leveraging AI, IoT, and real-time analytics, companies can proactively prevent failures, minimize unplanned downtime, and maximize operational efficiency. Industry leaders such as Bosch, Siemens, GE Digital, IBM, Honeywell, SKF, Denso, TIBCO, and Hitachi Vantara exemplify innovative approaches that are reshaping maintenance practices across fleets and manufacturing operations.

Standing out as a specialized partner, Radome Technologies delivers tailored predictive maintenance solutions, integrating AI, IoT, and cloud analytics to address the unique needs of automotive fleets and production lines. By choosing the right technology partner, automotive businesses can reduce costs, enhance reliability, and future-proof operations in today’s fast-paced, data-driven landscape.

Subscribe to get updates on our newsletter and whitepapers