Table of Contents

- Introduction

- What is Predictive Maintenance in Automotive Industry?

- How Predictive Maintenance Works in Automotive

- Key Benefits of Predictive Maintenance in Automotive Industry

- Use Cases of Predictive Maintenance in Automotive

- Challenges & Considerations

- Future Trends of Predictive Maintenance in Automotive Industry

- Conclusion

Introduction

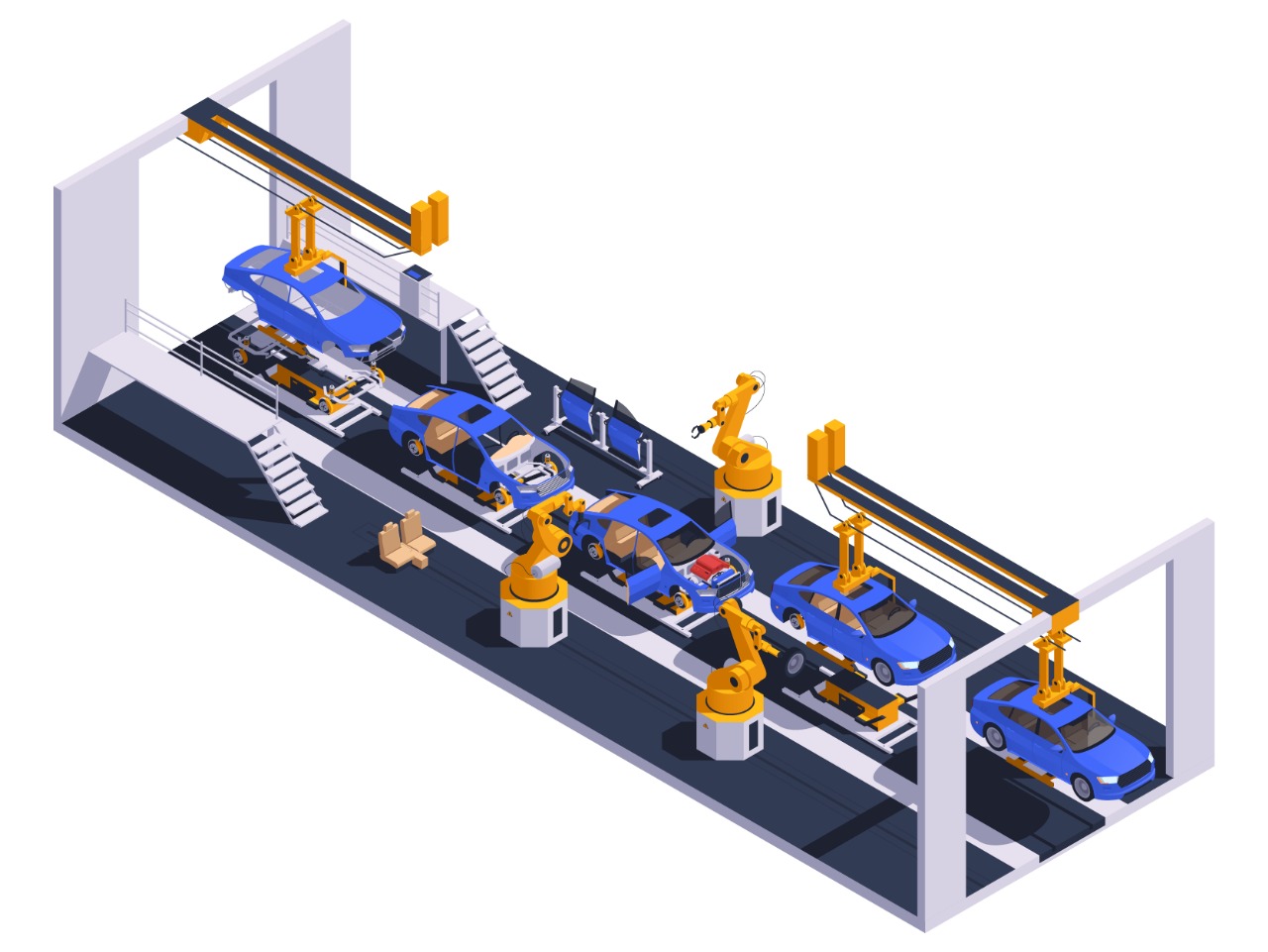

The automotive industry is at the forefront of digital transformation, with connected cars, electric vehicles (EVs), and smart mobility solutions changing the way vehicles are built and maintained. One of the most impactful innovations in recent years is predictive maintenance in manufacturing industry.

Unlike traditional maintenance approaches, predictive maintenance uses

AI, machine learning, IoT sensors, and predictive analytics to forecast when a vehicle component might fail. This shift not only reduces unexpected breakdowns but also enhances vehicle safety, cuts costs, and improves customer satisfaction.

What is Predictive Maintenance in Automotive Industry?

Predictive maintenance in automotive industry refers to the use of advanced data-driven technologies to monitor vehicle health and predict potential failures before they happen.

- Reactive maintenance = Fixing the vehicle only after it breaks down.

- Preventive maintenance = Scheduled check-ups regardless of actual need.

- Predictive maintenance = Continuous monitoring that tells you exactly when a part needs service.

This approach leverages real-time vehicle data collected from sensors, telematics, and cloud platforms to generate insights into wear and tear, ensuring that interventions are made at the right time.

How Predictive Maintenance Works in Automotive

Predictive maintenance combines IoT sensors, AI, big data analytics, and machine learning to detect and predict issues in vehicles.

-

Data Collection: : Sensors monitor temperature, vibration, tire pressure, fuel usage, battery health, and engine performance.

-

Data Processing:: AI and machine learning models analyze patterns to identify anomalies.

- Predictive Analytics: : Algorithms forecast when a component will fail or need service.

- Real-time Alerts: :

Fleet operators, OEMs, or drivers receive alerts for timely intervention.

This process enables condition-based maintenance instead of unnecessary routine servicing

Key Benefits of AI in Automotive Predictive maintenance

Adopting automotive predictive maintenance delivers significant advantages:

-

Reduced Downtime: : Vehicles spend less time in workshops and more time on the road.

-

Cost Efficiency: : Eliminates unnecessary servicing and minimizes major repair costs.

- Extended Vehicle Lifespan: :Early fault detection prevents long-term damage.

- Improved Safety & Compliance: :

Predicting failures reduces accident risks.

-

Higher Customer Satisfaction: :

Drivers and fleet owners enjoy smooth, uninterrupted operations.

According to industry studies, predictive maintenance can reduce maintenance costs by up to 25% and downtime by 45%.

Use Cases of Predictive Maintenance in Automotive

Predictive maintenance is already making waves across different areas of the automotive sector:

-

Fleet Management: Logistics and transportation companies use predictive analytics to keep trucks and buses road-ready.

-

OEMs (Original Equipment Manufacturers):

Automakers integrate predictive systems to enhance vehicle warranties and service.

-

EV Battery Monitoring: Predicting charging cycles and battery degradation in electric vehicles.

- Aftermarket Service Providers: Service centers use predictive maintenance solutions to upsell proactive repairs.

These predictive maintenance use cases in automotive show how businesses save costs and improve reliability.

Challenges & Considerations

Despite its benefits, predictive maintenance faces some challenges:

-

Data Integration: :

Combining data from different vehicles, models, and systems can be complex.

-

Upfront Costs: Requires investment in IoT sensors, AI systems, and skilled workforce.

- Cybersecurity Risks: :

Connected cars face vulnerabilities in transmitting data.

- Skill Gap: : Automotive technicians need training to work with AI-driven tools.

Companies must weigh ROI vs. investment when implementing these solutions.

Future Trends of Predictive Maintenance in Automotive Industry

The future of predictive maintenance in automotive industry is being shaped by next-gen technologies:

- AI & Machine Learning: More accurate predictive analytics.

- Digital Twins: Virtual models of vehicles to simulate and predict failures.

-

Integration with Autonomous Vehicles:

Self-driving cars will rely heavily on predictive systems.

- Smart EV Maintenance: Monitoring EV motors, charging systems, and batteries.

- Cloud & Edge Computing: Faster, real-time vehicle health monitoring.

The adoption curve shows that predictive maintenance will soon become a standard practice in automotive manufacturing and fleet management.

Conclusion

Predictive maintenance in automotive industry

is revolutionizing how vehicles are maintained, ensuring reliability, cost-efficiency, and safety. By leveraging AI, IoT, and predictive analytics, automotive companies can minimize breakdowns, extend vehicle life, and improve customer trust.

As the industry embraces electric and autonomous vehicles, predictive maintenance will play a central role in shaping the future of mobility. Companies that adopt it today will gain a competitive edge in tomorrow’s automotive landscape.

Want to Know More? Schedule a Demo Call.