As aviation spreads its wings, reliability, cost-efficiency, and safety have become

non-negotiable priorities for airlines. A simple part failure in the aircraft causes

downtime, which leads to potential business loss. This has compelled the airline and

other fleet management companies to prioritize aircraft

health monitoring in line with ongoing market demands. Companies are

leaning towards aircraft health monitoring systems

(AHMS) for extracting performance and maintenance data insights on a

real-time basis for extending the shelf life of machines.

This blog focuses on the vital concepts on aircraft health monitoring, its impact

on predictive maintenance, with a business case study and a few challenges.

But first, let us understand…

What is Aircraft Health Monitoring?

Aircraft Health Monitoring (AHM) is a system that leverages machine sensors and

hardware components to gather and analyze aircraft-generated data for predicting the

condition and performance of airplanes. It flags potential anomalies through predictive

insights, streamlining potential downtime and other sensor breakdowns. In simpler

words, it optimizes operational performance, accelerates fleet availability to boost

their business productivity, and performs predictive maintenance

operations.

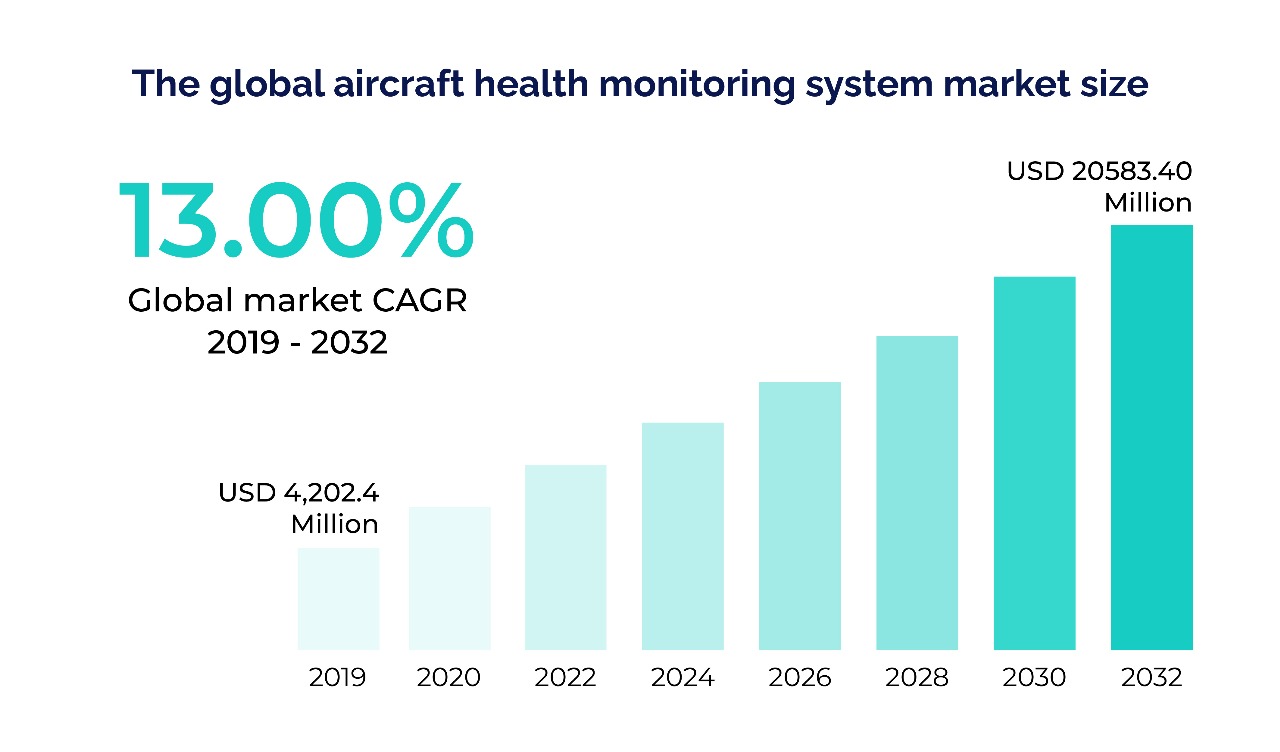

According to Fortune Business Insights, the

global aircraft health monitoring market size

is predicted to surpass $ 20.5 billion by 2030 at a striking CAGR rate of 13%.

Moreover, Aircraft Health Monitoring (AHM) prioritizes data analysis from the sensors located within the machine for predictive insights. Next in line, we will understand the AHMS contribution in predictive maintenance

The Role of Aircraft Health Management Systems in Predictive Maintenance

Companies that are enabling aircraft

health monitoring have witnessed measurable results across various operational

processes involved in aviation and fleet management.

According to a survey report, organizations

with predictive maintenance strategies have a 25-30% reduction in maintenance cost, and

35-45% have successfully reduced downtime.

- Predictive Maintenance:AHM detects early signs of component wear or failure, allowing maintenance before a breakdown happens. This reduces unscheduled maintenance and prevents in-flight issues.

Reduced Aircraft Downtime: By identifying problems early and planning maintenance ahead of time, airlines can keep aircraft in service longer and minimize AOG (Aircraft on Ground) situations.

Optimal Flight Reliability & Safety: Continuous monitoring of critical systems improves flight safety by reducing the risk of undetected system failures.

Real-time Alerts & Decision Support: Airlines and MRO teams receive real-time data and alerts, allowing faster and smarter decision-making during flight and on the ground.

Improved Fleet Management: Airlines can track the health of their entire fleet from a central system, making it easier to schedule maintenance and swap aircraft as needed.

Enhanced Regulatory Compliance: Automated health records and fault tracking help ensure compliance with aviation regulations and simplify compliance audits.

Data-Driven Insights: AHM platforms collect huge volumes of flight and system data, enabling big data analytics to identify design flaws, improve training, and even enhance fuel efficiency.

Seamless Passenger Experience: Fewer delays and cancellations due to maintenance issues lead to better on-time performance and a smoother travel experience for passengers.

Navigating Challenges in Aircraft Health Monitoring Implementation

The aircraft health monitoring systems offer pivotal benefits; however, several organizations face certain roadblocks during the implementation process, which hinder their operational activities rapidly. 60% of Indian carriers cited cost concern as one critical factor in adopting AHMS solutions. Some of the other hurdles that can be witnessed are:

Incompatibility with Legacy Aircraf Organizations often operate mixed fleets, where legacy aircraft lack modern sensor setups. Usually, installing AHM systems requires a middleware solution to avoid any negligence in the safety compliance norms.

Best fix: Business leaders should focus on customizable architecture that functions with both modern and legacy architectures for seamless fleet operations.

Data Security Threat The AHM system transmits confidential operational data across the dashboards, and without a robust cybersecurity framework, the organization can become vulnerable to compliance threats and data breaches.

Best fix: Corporations must prioritize enhancing their cybersecurity protocols to align with AHMS installation.

Adoption Measures Implementing AHMS software often poses adoption challenges, including data encryption and decryption concerns.

Best Fix: The organizations can use a trained AHMS solution for seamless adoption. An alternative approach for these concerns is to look out for an industry expert who focuses on AHMS and similar software solutions, and Radome Technologies is one such!

About the company

Radome Technologies offers a

top-of-the-line Aircraft Health Monitoring System (AHMS), which is meticulously

designed using AI & machine learning to execute predictive maintenance across fleet

management operations. Our platform seamlessly indicates the real-time diagnostic

insights of the aircraft on a real-time basis. It also monitors the fault detection and

remaining useful life (RUL) estimations for supporting the organization in optimizing

its business operations, minimizing downtime, and updating the aircraft availability.

Our ProHM+ solution integrates seamlessly with your existing mixed fleets and

legacy systems without any interruption. In addition, our team of experts customizes

the platform parameters as per your specific requirements, ensuring the solution aligns

perfectly with your operational needs.

Radome Technologies’ ProHM+ is the ultimate solution for your business for

de-escalating delayed maintenance, aircraft health monitoring, fragmented data on

aircraft health, and others.

If you are on the lookout to find the right AHMS services provider, we equip

corporations with scalable architecture and sensor analytics in our unified solution

that can reinforce your business performance to act smarter, efficiently, and make

better decisions.

Case Study: Productive Impact of Using Aircraft

Health Monitoring Systems (AHMS)

Source

Tech Mahindra is an Indian multinational corporation that offers IT consulting and

digital solutions for its clients. It also focuses on Aircraft Health Monitoring

Systems (AHMS) using IoT, Big Data, and cloud computing.

Overview + Challenge:

A leading European Aerospace establishment wanted to seek collaboration with Tech

Mahindra for de-escalating operational setbacks arising due to flight cancellations and

delays due to defective anomalies. They focused on delivering aircraft health

information in real time to their ground staff and on inculcating the practice of using

aircraft health monitoring systems.

Execution:

The client required a big data analytics ecosystem; therefore, the AHMS solution

enabled the seamless transmission of IoT data for analysis purposes. The ground staff

were equipped with real-time data insights in the dashboard, and other alert

notifications supported them to function optimally.

The predictive analytics empowered the establishment with optimal maintenance

planning, and the other technical instructions yielded significant results in full

capacity efficiency.

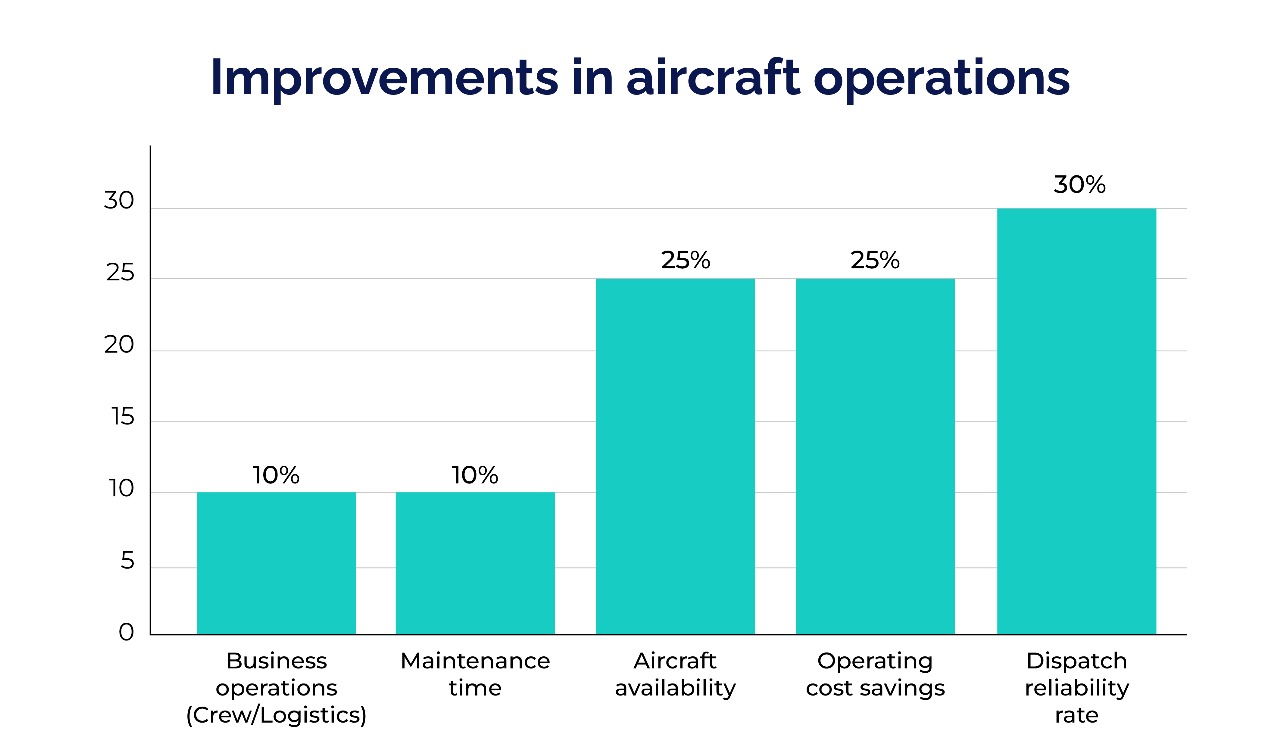

Outcome:

- The results were astonishing as there was an improvement in the dispatch reliability rate up to 25-30%

- 25% savings in operating costs due to adequate troubleshooting. It also enhances the aircraft availability with minimal disruptions in flights.

- Lastly, it improved the maintenance time by 10% and eased other business operations such as crew planning and logistics.

In Summary

Aircraft health monitoring has transformed from just an “upgrade” to a must-have solution for driving optimal operations, data-driven decision-making, and more. The advancement in the aviation industry in predictive maintenance has paved the way for integrating aircraft health monitoring systems for minimum fleet downtime. This ensures the business continuity is uninterrupted and empowers the business to focus on other critical operational aspects for smarter capital management.