In today’s fast-paced industrial world, predictive maintenance is no longer a futuristic concept—it’s a competitive necessity. With the rise of intelligent technologies like AI, machine learning, and IoT, predictive maintenance is redefining how industries approach equipment reliability, performance, and uptime. From manufacturing floors to aerospace hangars, organizations are adopting predictive maintenance systems to move from reactive repair to proactive precision. But what exactly is predictive maintenance, how does it work, and why is it transforming every industry?

What Is Predictive Maintenance?

Predictive maintenance (PdM)

is a proactive maintenance strategy that uses real-time data from

sensors, machine logs,

and external conditions to predict when equipment is likely to fail or require

servicing.

Unlike preventive maintenance—which relies on fixed schedules—predictive

maintenance only intervenes when it's actually needed,

significantly reducing unnecessary downtime, maintenance costs, and component

failures.

These systems leverage historical and real-time data, often powered by AI in

predictive maintenance, to analyze patterns, detect anomalies, and forecast

potential failures before they happen.

How Predictive Maintenance Systems Work

- Sensor Networks: Embedded in machines to collect real-time data (vibration, temperature)

- IoT Platforms: To transmit and aggregate machine data

- AI & Machine Learning Algorithms: To analyze the data for failure prediction

- Integration with CMMS or ERP: To automate service workflows

This ecosystem of data and intelligence transforms maintenance from a reactive cost center to a strategic efficiency enabler.

Predictive Maintenance in Manufacturing: A Game-Changer

The predictive maintenance in manufacturing sector has witnessed a massive transformation due to AI integration. Heavy machinery, conveyor systems, motors, and CNC machines are now equipped with smart sensors. When combined with AI for predictive maintenance in manufacturing, these machines can now alert operators of deteriorating conditions before failure.

- Reduced Unplanned Downtime: Real-time insights prevent sudden machine stoppages.

- Increased Equipment Lifespan:Early detection minimizes severe damage.

- Higher Productivity: Machines operate optimally with minimal intervention.

- Lower Maintenance Costs: No more over-maintaining assets that are still healthy.

With AI in predictive maintenance, manufacturers can prioritize maintenance tasks, allocate resources effectively, and extend asset life.

Aircraft Predictive Maintenance: Flying Smarter with AI

In aviation, even minor component failures can lead to serious risks and high economic losses. That's why aircraft predictive maintenance has become a mission-critical application of AI and IoT.

Predictive Maintenance in Aircraft Example:

Consider a jet engine equipped with thousands of sensors monitoring temperature, pressure, and vibration. Using predictive maintenance of aircraft engine, the system analyzes fluctuations and historical performance to detect anomalies that could indicate compressor blade wear or turbine imbalance. This insight allows maintenance crews to intervene before failure, improving safety and reducing grounded aircraft time.

Importance of Predictive Maintenance in Aircraft:

- Passenger Safety: Early issue detection ensures compliance with safety standards.

- Reduced Flight Delays: Airlines can avoid unexpected cancellations or emergency maintenance.

- Cost Optimization: Replacing components only when necessary cuts excessive maintenance costs.

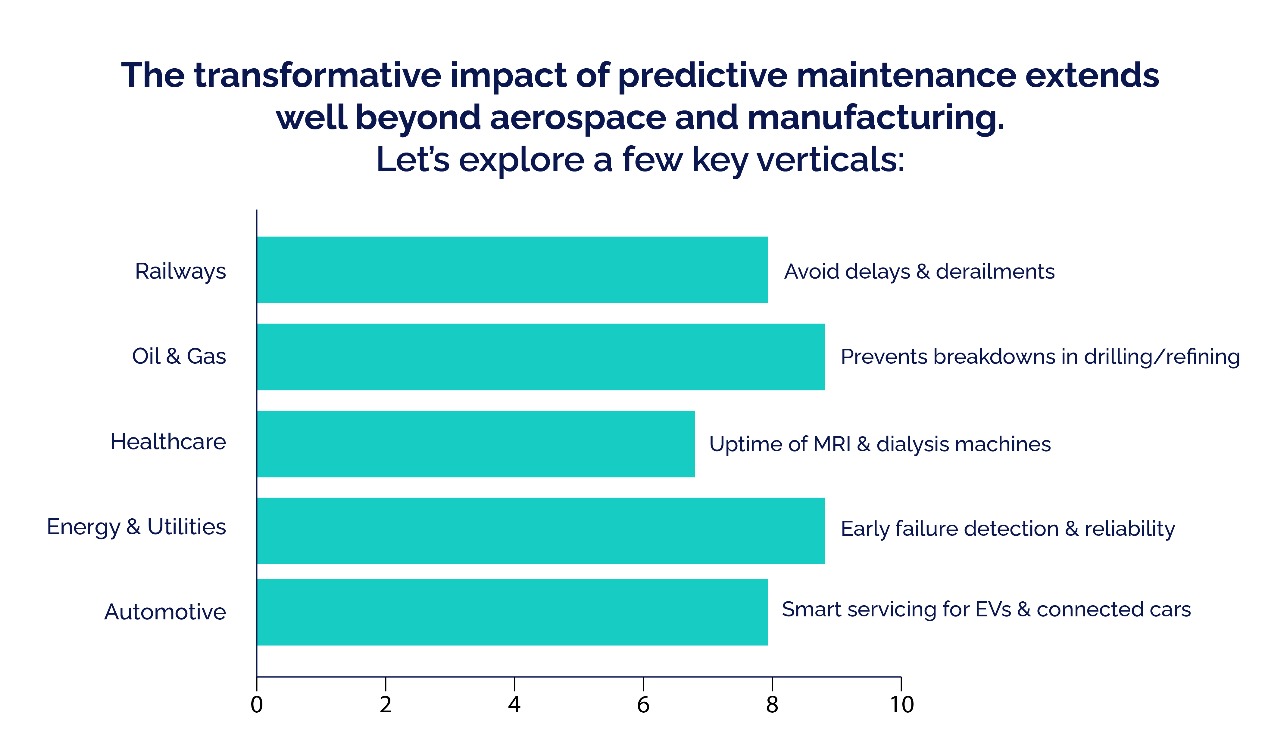

- Automotive: Predicts drivetrain, battery, and engine health, enabling smart servicing for electric vehicles and connected cars.

- Energy & Utilities: Helps monitor turbines, pipelines, and transformers for early failure detection and increased reliability.

- Healthcare: Ensures uptime of critical medical equipment such as MRI and dialysis machines. costs.

- Oil & Gas: Prevents catastrophic breakdowns in drilling and refining machinery.

- Railways: Monitors brake systems, wheels, and track conditions to avoid delays and derailments.

- Operational Efficiency: Machines work longer and smarter with minimal human intervention

- Cost Savings: Avoiding catastrophic failures leads to significant ROI.

- Sustainability Fewer breakdowns mean less material waste and lower energy consumption.

Predictive Maintenance in Aviation Using Artificial Intelligence:

AI takes aviation maintenance to the next level by handling massive datasets from multiple aircraft. Algorithms analyze sensor data, flight patterns, weather impacts, and usage anomalies to continuously optimize performance predictions. The result is a smarter, faster, and more reliable predictive maintenance system for modern aviation fleets.

Predictive Maintenance Across Industries

The transformative impact of predictive maintenance extends well beyond aerospace and manufacturing. Let’s explore a few key verticals:

From predictive maintenance in aircraft to real-time monitoring in factories, PdM is delivering bottom-line impact across the board.

Why Predictive Maintenance Is the Future

The reason predictive maintenance is transforming every industry boils down to its measurable value:

In a world demanding zero downtime and maximum output, predictive maintenance is the intelligent backbone of industrial reliability.

Final Thoughts

As industries increasingly rely on connected systems and digital transformation, predictive maintenance is emerging as a cornerstone of smart operations. The shift from reactive to predictive isn't just a technical upgrade—it’s a strategic leap. Whether it’s an AI-powered visual inspection system on a shop floor or a predictive maintenance model safeguarding a jet engine, this technology is redefining what’s possible across every sector. If you’re not exploring predictive maintenance today, you’re already a step behind

Want to Know More? Schedule a Demo Call.