Introduction

In today’s hyper-competitive manufacturing world, maintenance strategy isn’t just about keeping machines running — it’s about driving efficiency, reducing downtime, and staying ahead of competitors. As factories embrace Industry 4.0 and AI-driven automation, two dominant approaches to equipment care stand out: predictive maintenance and preventive maintenance.

But here’s the big question for 2025: Which one is right for your factory? Let’s break down both strategies, compare their impact, and help you make the right decision.

What is Preventive Maintenance?

Preventive maintenance is a scheduled, time-based approach to servicing machines. It means inspecting, repairing, or replacing parts before they fail, based on calendar schedules or usage cycles.

Examples in a Factory:

- Lubricating conveyor belts every 30 days.

- Replacing bearings after every 10,000 operating hours.

- Routine calibration of robotic armsn.

Pros:

- Simple to implement

- Prevents unexpected breakdowns

- Extends equipment lifespan

Cons:

- Can lead to over-maintenance (replacing parts too early)

- Higher labor costs due to unnecessary checks

- Doesn’t adapt to real-time machine conditions

What is Predictive Maintenance?

Predictive maintenance (PdM) leverages IoT sensors, AI, and real-time monitoring to predict when equipment is likely to fail. Instead of scheduled intervals, it uses condition-based monitoring and data analytics.

- Using vibration sensors to detect bearing wear.

- AI models predicting spindle overheating.

- Real-time monitoring of tyre or TRB (tapered roller bearing) components.

Examples in a Factory:

- Reduces downtime by up to 50%.

- Cuts maintenance costs by 30–40%.

- Maximizes equipment life.

- Data-driven and highly accurate

Pros:

- Requires investment in IoT & AI tools.

- Needs skilled workforce for implementation

- Initial setup can be time-consuming

Cons:

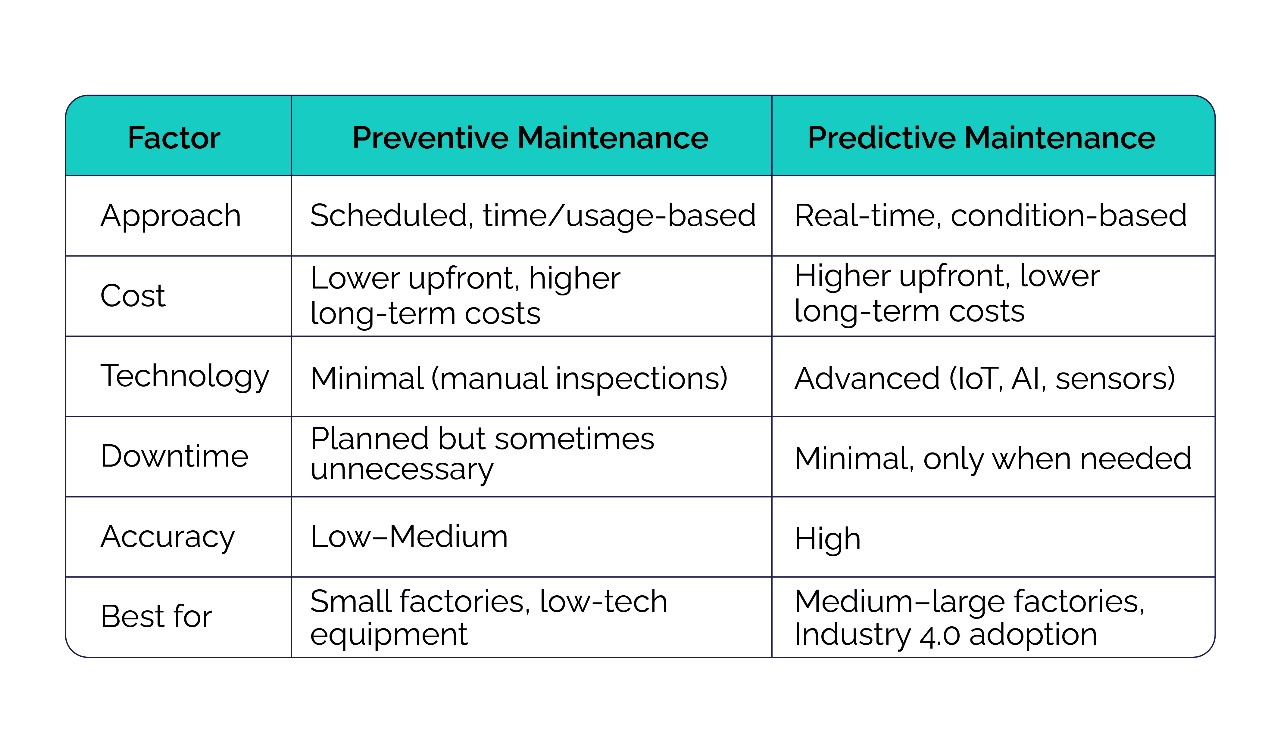

Predictive vs Preventive Maintenance: The Key Differences

Which Strategy is Right for Your Factory in 2025?

Choosing between predictive and preventive maintenance depends on:

-

Factory Size:

- Small-scale units may benefit from preventive maintenance due to lower costs and simpler processes.

- Large-scale factories with expensive, high-speed machines benefit more from predictive maintenance.

-

Industry Needs:

- Automotive & Aerospace Predictive is essential for precision and safety.

- FMCG & Food Processing Preventive may work due to lower complexity.

- Heavy Machinery Predictive ensures uptime and reduces costly breakdowns.

The Role of Industry 4.0 in Maintenance

By 2025, Industry 4.0 technologies such as AI, IoT, cloud analytics, and digital twins are reshaping maintenance. Predictive maintenance integrates seamlessly into smart factories by:

-

Using AI-based defect detection in bearings and tyres

-

Running edge AI for real-time inspection without human delays

-

Applying machine learning models to optimize inspection cycles

How to Transition from Preventive to Predictive Maintenance

If your factory currently runs on preventive maintenance, here’s how to move toward predictive:

- Start Small – Implement IoT sensors on critical equipment.

- Collect Data – Gather vibration, temperature, and wear data.

- Adopt AI Tools – : Use predictive algorithms for defect detection.

- Train Staff – Upskill workers for AI-driven monitoring.

- Scale Gradually – Expand predictive maintenance across all production lines.

Conclusion: The Future of Factory Maintenance in 2025

The choice between predictive vs preventive maintenance isn’t about which is “better,” but about which fits your factory’s size, budget, and goals. Preventive maintenance is cost-effective for smaller setups, while predictive maintenance delivers long-term savings, efficiency, and resilience for larger factories embracing Industry 4.0.

Bottom line: If your factory wants to stay competitive in 2025, predictive maintenance is no longer optional — it’s a necessity.

Want to Know More? Schedule a Demo Call.