Manufacturing leaders today are operating in an environment defined by cost pressure, supply chain volatility, quality expectations, and workforce constraints. Traditional automation alone is no longer enough to manage this complexity. This is where AI in manufacturing is becoming a strategic lever rather than a technology upgrade.

Unlike earlier waves of digitization, artificial intelligence in manufacturing focuses on learning from operational data and improving decisions over time. From the shop floor to enterprise planning, AI enables manufacturers to move from reactive responses to predictive and intelligent operations.

Artificial Intelligence in Manufacturing Explained Clearly

Artificial intelligence in manufacturing refers to systems that analyze production data, identify patterns, and support decisions with minimal human intervention. Unlike rule-based automation, AI systems continuously learn from machine behavior, process variations, and operational outcomes.

In practical terms, AI-powered manufacturing allows factories to detect issues earlier, respond faster, and optimize performance across machines, lines, and plants. AI does not replace human expertise. It augments it with insights that are difficult to identify manually at scale.

Core Capabilities That Define AI Manufacturing Solutions

Modern AI manufacturing solutions are built to address real operational challenges rather than abstract innovation goals. Their value lies in a few core capabilities:

- Continuous pattern recognition across machine, process, and quality data

- Predictive decision support for maintenance, production, and planning

- Automated quality deviation detection before defects escalate

- Adaptive production optimization based on real-time conditions

These capabilities are delivered through purpose-built AI manufacturing software that integrates with existing systems such as MES, ERP, and sensor networks, making adoption practical even in brownfield environments.

AI Use Cases in the Manufacturing Industry

The adoption of AI is accelerating because the use cases are proven and measurable. Common AI uses cases in manufacturing industry include quality improvement, operational efficiency, and asset reliability.

In quality operations, AI systems analyze images and process data to detect deviations earlier than manual inspection. In production planning, AI optimizes schedules by balancing demand variability, machine availability, and resource constraints. In energy management, AI helps reduce waste by identifying inefficiencies across operations.

One of the most impactful applications is predictive maintenance using AI, which has become a foundation for many industrial AI deployments.

Predictive Maintenance Using AI as a Business Advantage

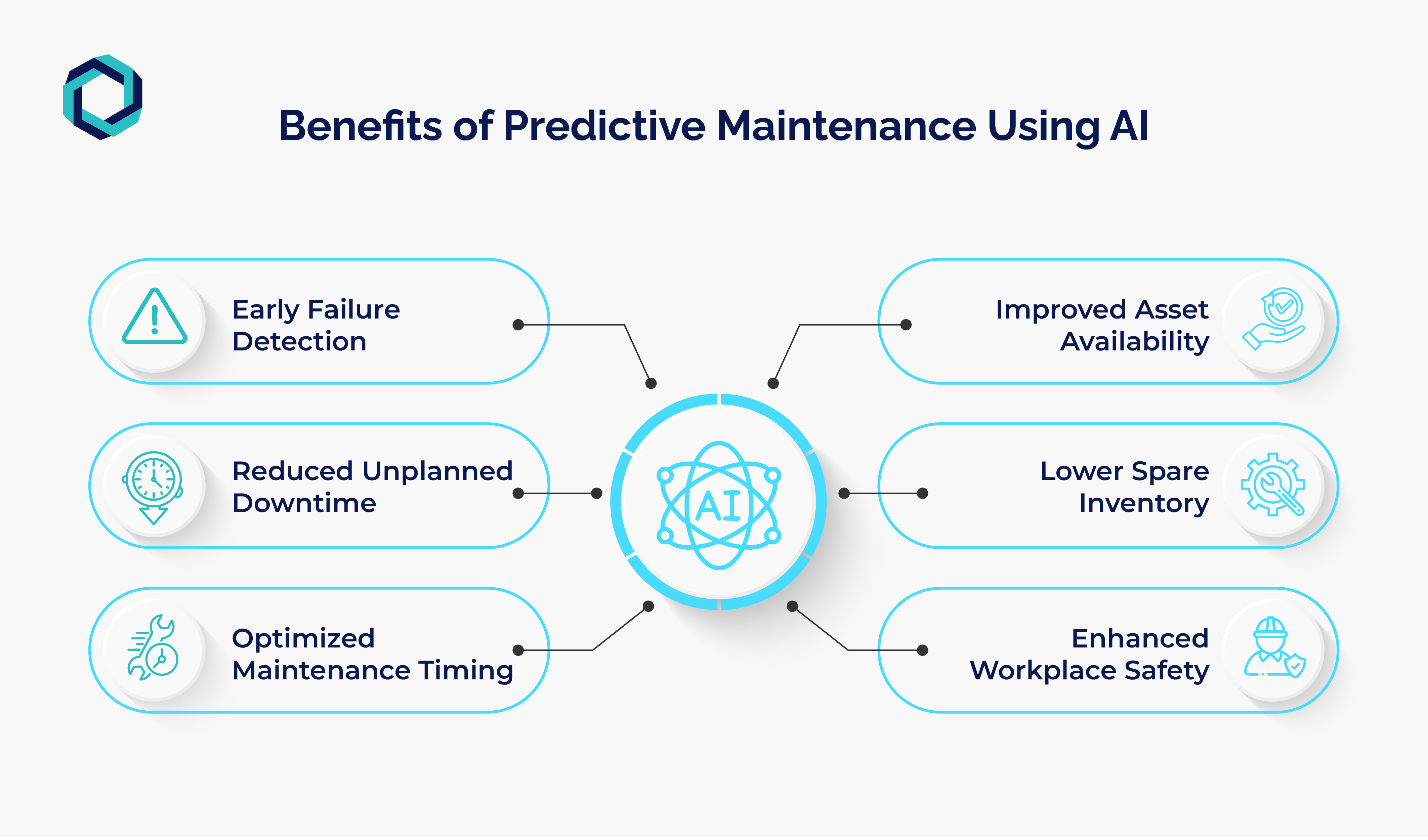

Traditional maintenance approaches rely on fixed schedules or reactive interventions, both of which lead to unnecessary downtime or unexpected failures. Predictive maintenance using AI changes this model by identifying early signs of equipment degradation. Business leaders can learn how AI enhances manufacturing reliability to prevent failures and improve overall asset performance.

- Early Failure Detection

- Reduced Unplanned Downtime

- Optimized Maintenance Timing

- Improved Asset Availability

- Lower Spare Inventory

- Enhanced Workplace Safety

By analyzing vibration, temperature, current, and historical performance data, AI systems predict failures before they occur. This allows maintenance teams to intervene at the right time, reduce spare part inventory, improve asset availability, and enhance safety. For many manufacturers, predictive maintenance is the first step toward broader adoption of AI in manufacturing, as the ROI is clear and immediate.

Digital Transformation in Manufacturing Using AI

AI plays a critical role in enabling digital transformation, but it is not the transformation itself. Digital transformation in manufacturing using AI works when intelligence is layered onto connected data streams across the enterprise.

Successful manufacturers focus on data quality, system integration, and process alignment before scaling AI initiatives. When implemented correctly, AI enables faster decision cycles, better cross-functional coordination, and improved resilience during disruptions. This approach ensures that transformation efforts move beyond isolated pilots toward enterprise-wide impact.

AI in Smart Manufacturing and Intelligent Operations

AI in smart manufacturing supports the shift toward systems that sense, analyze, and act with minimal delay. These environments rely on closed-loop feedback between machines, operators, and enterprise systems.

Rather than removing human control, smart manufacturing environments enable collaboration between people and industrial AI systems. Operators gain better visibility, managers gain predictive insights, and organizations gain consistency across locations. This intelligence-driven approach helps manufacturers scale best practices while maintaining operational flexibility.

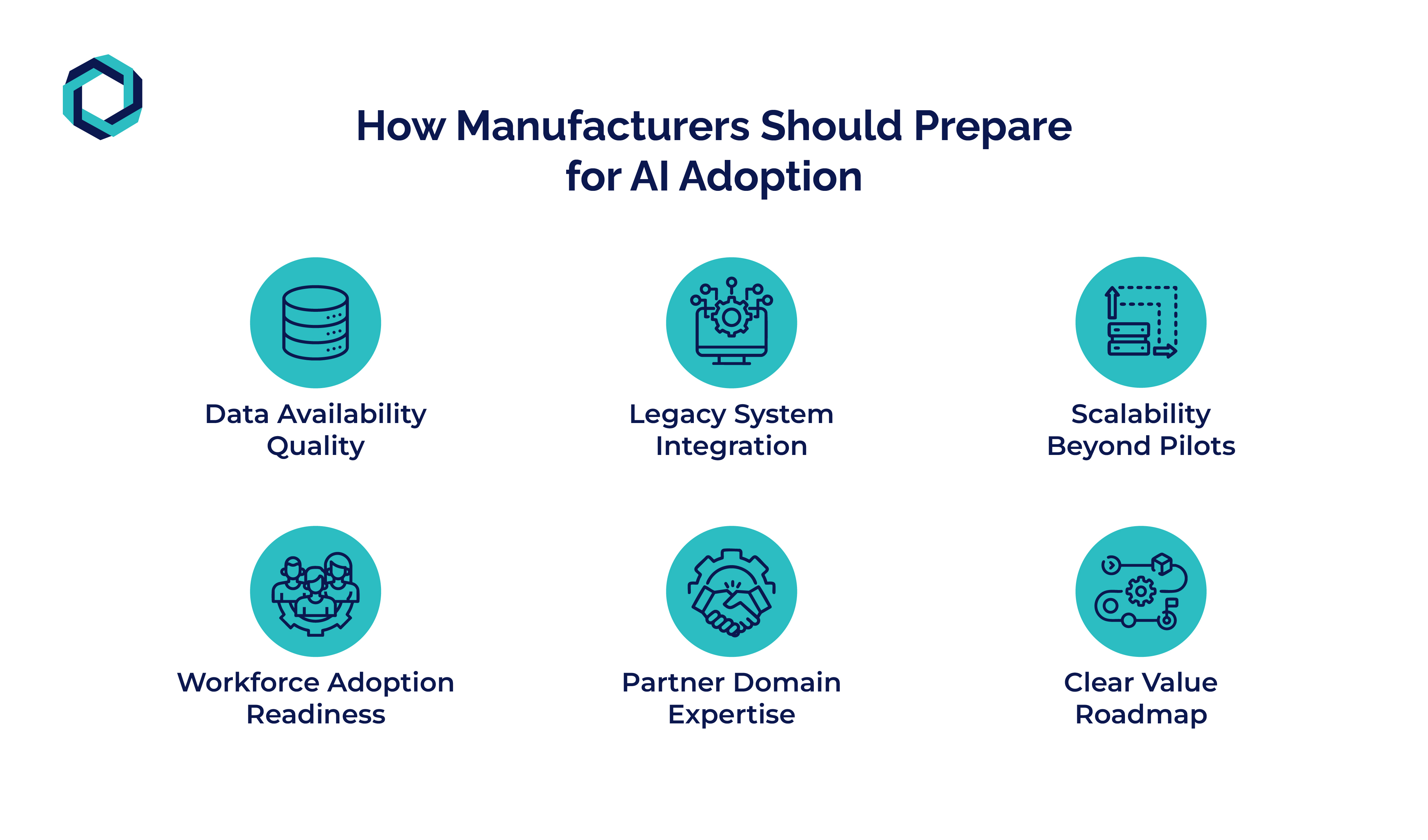

What Manufacturing Leaders Should Evaluate Before Adopting AI

For C-suite leaders, the success of AI initiatives depends less on algorithms and more on execution readiness. Key evaluation factors include data availability, integration with existing infrastructure, scalability beyond pilot projects, and workforce adoption.

- Data Availability Quality

- Legacy System Integration

- Scalability Beyond Pilots

- Workforce Adoption Readiness

- Partner Domain Expertise

- Clear Value Roadmap

Selecting the right AI manufacturing solutions partner is critical. Manufacturers should look for domain expertise, proven deployments, and a clear roadmap from experimentation to scale. AI must deliver measurable business outcomes, not just technical performance.

Many manufacturers understand the potential of AI but struggle to translate intent into operational impact. This is where execution matters more than experimentation.

Radome Technologies And Its ProHM+ The Ultimate Game Changer For Manufacturing Industries

Radome Technologies helps manufacturers operationalize AI by focusing on real production constraints, not theoretical models. Its ProHM+ platform continuously captures machine signals such as vibration, temperature, load, and operating cycles, transforming raw data into actionable maintenance and performance insights. The system identifies early deviations, supports condition-based maintenance, and stabilizes operations without disrupting existing workflows.

ProHM+ Built for Industrial Reality

- Continuous asset monitoring across lines and plants

- Early fault detection using AI-driven pattern analysis

- Seamless integration with existing MES and ERP systems

- Clear insights for maintenance, reliability, and operations teams

Radome Technologies enables manufacturers to move beyond pilots and achieve reliable, scalable AI adoption.

Ready to turn AI into a measurable operational advantage? Connect with Radome Technologies to see how ProHM+ can strengthen your manufacturing operations.

Conclusion

AI is no longer an emerging concept in the manufacturing industry. It is becoming a core operational capability. Manufacturers that invest early in AI in manufacturing build learning systems that improve with time, while late adopters risk falling behind in efficiency, quality, and resilience. The advantage lies not in experimentation, but in disciplined execution at scale.

Want to Know More? Schedule a Demo Call.